Choosing the right battery partner is essential to the long-term success of any battery-powered product. Having spent months & years designing the perfect product, the final piece that ties everything together is the power source. We believe there are a number of important factors to consider when selecting the perfect partner to power your product.

Quality

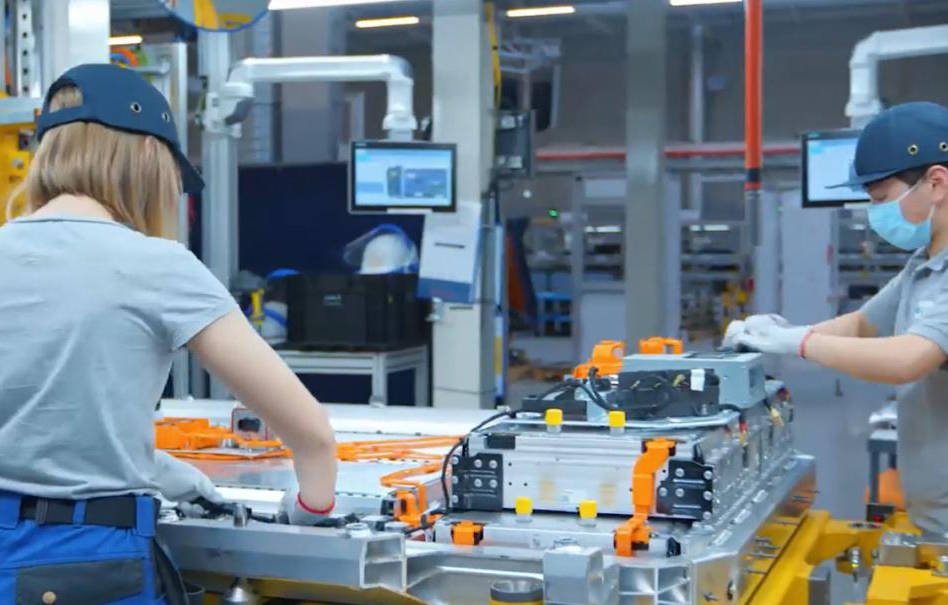

In order to maintain the long-term performance of your product it is important to have a high-quality power source at the heart of it. At Eco Earth Battery we have a number of measures in place to ensure we only produce high-quality products. These quality measures we have in place start with the operatives who will be assembling your products. Each operative that is on our production floor has had, at a minimum, four weeks’ worth of training before they work on live products. We do this to ensure that each of our production operatives is trained to a high standard to reduce waste and the potential for product defects as a result of human error. This has resulted in a 1.7 parts per million rate.

At Eco Earth Battery we use a FMEA (Failure Mode and Effect Analysis) to allow us to take a proactive approach in identifying any potential failure modes and asses the effect it will have on our products and our customers. This will benefit our customers by minimizing the risks of any potential failure modes, leading to increased productivity, an increase in OTIF which ultimately leads to increased satisfaction.

To ensure that the finished products we ship to our customers are of high standard, we conduct end-of-line tests that are designed to pinpoint any imperfections that have occurred during the manufacturing process. These procedures are performed in labs that have had their capabilities assessed and certified. To continue reading about our testing procedures please click here.

Geography

Part of At Eco Earth Battery’s 5-year plan is to be closer to our customers. To take steps towards this, the business is currently working towards establishing a sales base in GB and from there plans to establish a manufacturing facility within the EU. This move will aim to reduce the distance the finished product will need to travel. In turn, this will not only decrease costs associated with moving products but will also allow our customers to have their batteries packed sooner in order to get their products to market quicker.

Reliability

This aspect of your decision not only takes into account the reliability of your eventual product but also the reliability of the supplier to deliver your product on time. An unreliable supplier could lead to both delaying your product’s entry into the market and causing performance issues well into its product lifecycle. We are proud of our on-time delivery rate, sitting at 98% on-time delivery rate. We ensure that we deliver our products in a way that will not cause knock-on issues for our customers.

As a business we currently sit at 1.7 parts per million, this is in part due to our supplier approval process. All of our Cat A suppliers will complete ISO:9001 or ISO:13485, they will also sign up for our supplier quality plan and finally, complete a supplier questionnaire. On top of this, each part received at our inwards good station is checked to ensure they meet our quality standards. Each batch will then be given a batch reference which allows traceability. If there is a part that doesn’t meet our quality standards the part is identified and then placed in the suspect material bay with corrective action procedures to follow.

Technical

It is important that whoever takes on your battery project has the technical knowledge and experience to achieve your goals. Every project has a dedicated project manager who will not only communicate with the customer, they will also converse with each department to ensure the best product is delivered. The team will use their technical knowledge and expertise to keep up with the latest trends and apply that to your battery pack throughout the course of your project. The technical knowledge that Eco Earth Battery has is backed by 40 years of battery manufacturing experience.

In summary, when choosing a battery partner to power your product, there are several important factors to consider. Quality is essential to maintain the long-term performance of your product, and Eco Earth Battery has several measures in place to ensure high-quality products. Geography is also important to limit lead times and reduce the overall costs of the project. Reliability is crucial to the overall success of a project whether its delivery times or product reliability. Finally, having technical expertise for any supplier is needed to successfully deliver on all of the aspects wanted by the customer.

If your battery partner is not providing all of these aspects this may affect the performance of your product when it comes to market. If you want to learn more about how Eco Earth Battery is able to help you with all of these aspects, please visit our contact us page.